Understanding Truck Mounted Attenuators (TMA)

Prologue

Last November we introduced you to the Last Line of Defense; a Traffic Pro Bed option that we first offered to Prince George’s County Department of Public Works and Transportation (PGCDPW&T). Just as it has for PGCDPW&T, this innovation can make all the difference for your work zones, your service vehicles, and most importantly your crews. The Last Line of Defense is a Metro Truck Mounted Attenuator (TMA) retrofitted directly to a Traffic Pro Bed, also known as your service vehicle.

What makes this Last Line of Defense different from a traditional TMA truck is that it is also a service vehicle that is loaded with equipment and not weighed down to crash truck specifications. This distinction means it is ineligible by federal mandate to be used as a crash truck. It cannot be used to satisfy any crash truck requirements.

However, as a Last Line of Defense, this product is still capable of preventing severe crashes and saving employees from work zone intruders, and below is the guide to prove it. Read below for a deep dive into the logic behind the Last Line of Defense. Follow this comprehensive guide into the world and reasoning behind TMAs, Crash trucks, Attenuators, Crash cushions, and what they mean to the lives that live in the traffic control industry every day.

Introduction

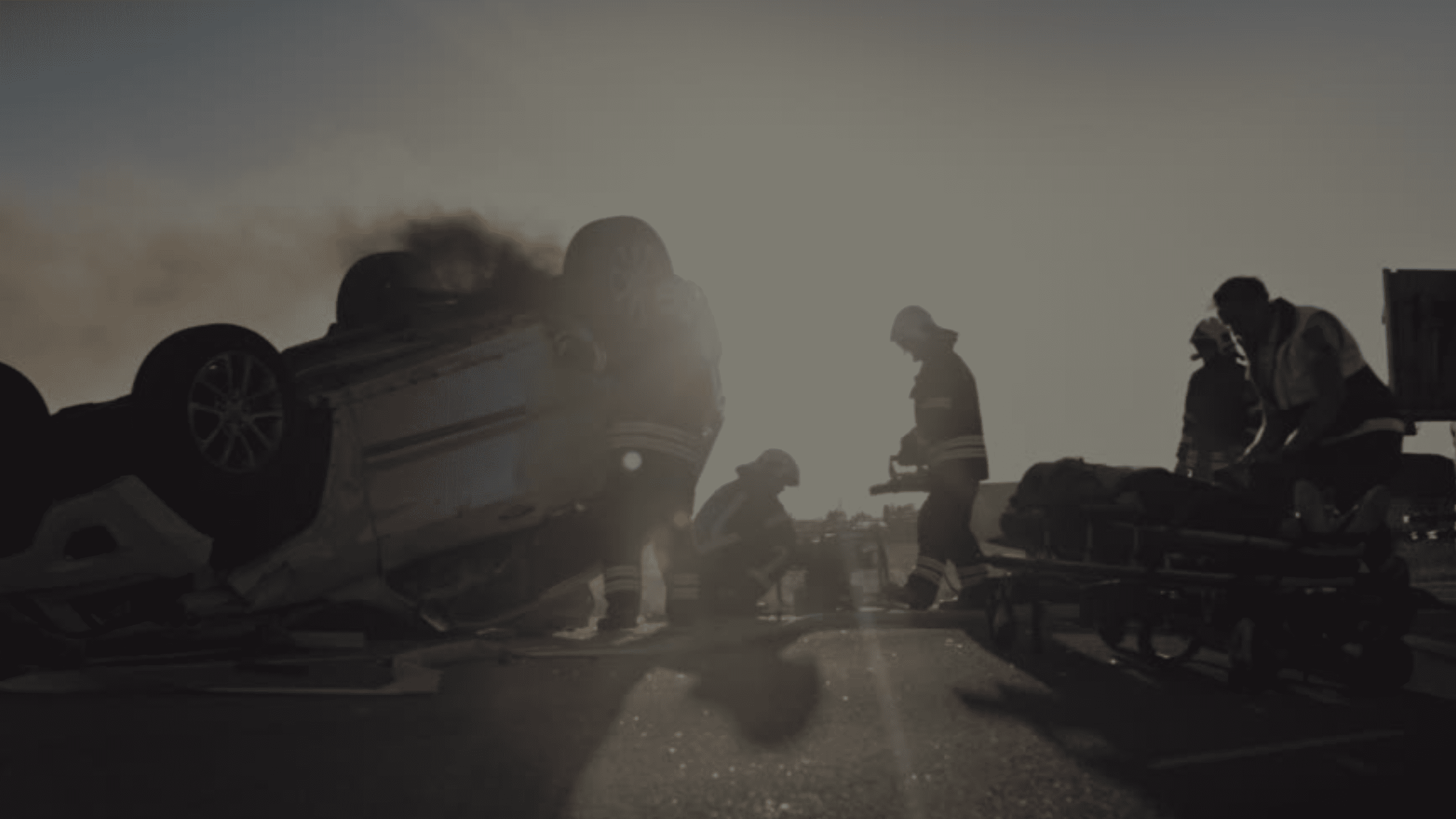

Truck Mounted Attenuators (TMA), also known as attenuator trucks or TMA crash trucks, are critical safety devices used in road construction and maintenance to protect both workers and motorists. These devices, which can be found as part of truck equipment or as standalone traffic control trucks, are designed to absorb and dissipate the kinetic energy of a collision, thereby reducing the impact force and minimizing injuries and damage. So what are Truck-mounted Attenuators and how do they work?

What Are Truck Mounted Attenuators?

A Truck Mounted Attenuator, often referred to simply as a TMA, is an energy-absorbing device attached to the rear of a truck or other vehicle. The primary function of an attenuator truck is to safeguard road workers and vehicle occupants from the impact of a collision by reducing its severity. The attenuator unit, typically made of materials like aluminum and steel, deforms upon impact to absorb and dissipate energy. This controlled deformation significantly lowers the risk of injury and damage during an accident.

The History of TMAs

The concept of TMAs, or crash attenuators, emerged in response to the growing need for enhanced safety measures in roadwork zones. The development of these devices dates back to the mid-20th century when increased traffic volumes and speeds led to higher accident rates in construction areas. Over the years, the design and functionality of TMAs have evolved, incorporating advanced materials and engineering principles to improve their effectiveness. The establishment of safety performance standards, such as those by the National Cooperative Highway Research Program (NCHRP) and the Manual for Assessing Safety Hardware (MASH), has further guided the development and implementation of TMAs. These standards ensure that TMAs, such as the Scorpion II from Traffix, meet rigorous safety requirements.

When and Where TMAs Are Required

Truck Mounted Attenuators are required in various situations, particularly in high-risk roadwork zones. They are commonly deployed:

- During road construction: To protect workers from errant vehicles.

- In maintenance operations: Such as painting, sweeping, and striping.

- For temporary lane closures: Providing a buffer zone for workers and equipment.

The use of TMAs is mandated by state regulations, often aligned with federal safety standards. States like California, Texas, Florida, and New York have specific requirements for the deployment of TMAs in construction and maintenance zones. These regulations ensure that adequate safety measures are in place to protect both workers and the traveling public.

Importance of TMAs

The importance of Truck Mounted Attenuators cannot be overstated. Here are some key reasons why they are essential:

Enhanced Safety: TMAs protect both road workers and motorists by mitigating the effects of vehicle collisions. According to the Federal Highway Administration (FHWA), work zone crashes resulted in over 700 fatalities in 2019 alone, highlighting the critical need for effective safety measures like TMAs.

Damage Reduction: By absorbing impact energy, TMAs minimize vehicle damage and the potential for secondary accidents, which can be more severe than the initial collision.

Compliance with Safety Standards: The use of TMAs ensures adherence to safety regulations and standards, reducing the risk of legal and financial repercussions for construction companies and government agencies.

Supporting Statistics

Statistics strongly support the use of TMAs. A study by the National Work Zone Safety Information Clearinghouse reported that the presence of TMAs in work zones significantly reduces the severity of crashes. Additionally, states that have implemented rigorous TMA regulations have seen a noticeable decline in work zone fatalities and injuries.

For instance, California’s Department of Transportation (Caltrans) reported a 15% decrease in work zone injuries after mandating the use of TMAs. Similarly, Texas observed a 10% reduction in fatal work zone accidents following the implementation of stringent TMA requirements.

Conclusion

Truck Truck-mounted attenuators play a vital role in ensuring the safety of roadwork zones. Their ability to absorb and dissipate impact energy reduces the severity of collisions, protecting both workers and motorists. The history, regulatory requirements, and statistical evidence underscore the importance of TMAs in maintaining safe roadways. As traffic volumes and construction activities continue to grow, the deployment of TMAs, including models like the Traffix Scorpion II, will remain a crucial element of road safety strategies. For those in need of these devices, various options are available on the market, including entire attenuator trucks for sale and stand-alone units ready for mounting from brands like Traffix devices.

Post Script

Reflecting on our journey through the world of Truck Mounted Attenuators (TMAs), the Last Line of Defense is a truly practical solution for increasing safety for work zone employees. This innovative option embodies a unique solution that bridges the gap between a fully equipped service vehicle and a traditional crash truck. This hybrid approach offers enhanced flexibility and utility in work zones while still providing critical protection against intrusions.

The essence of the Last Line of Defense lies in its dual functionality—combining the necessary tools and equipment for roadwork with the life-saving capabilities of a TMA. Although it doesn’t meet federal mandates for crash truck specifications, its role in enhancing safety for MOT crews and mitigating potential disasters is undeniable. Validating the importance of this Traffic Pro Bed option, this comprehensive guide has explored the logic, history, functionality, and the regulatory frameworks that govern their use TMAs.

While the Last Line of Defense in it of itself is so significant to the industry, we hope this innovation underscores the continuous need for advancements in road safety. As traffic conditions evolve and construction activities expand, solutions like the Last Line of Defense will be indispensable in protecting the lives of those who maintain our roadways. Embracing these advancements not only adheres to safety standards but also exemplifies a commitment to safeguarding our workforce and the traveling public.