COMPONENTS

These components are the TPB options that allow crews to realize the safety and ergonomic efficiency of the Traffic Pro Bed system. Learn below how the Employee Safety Unit (ESU), Cone Drive System, and Sign and Stand Box instill our company values and contribute to the Traffic Pro Bed system at large. Ultimately providing a safer, more efficient, and more versatile approach to traffic control.

OUR COMPONENTS,

YOUR TRAFFIC CONTROL VISION

Another worthwhile value of some of our components is their modularity. This makes them easy to install or replace, and ideal for building a specialized traffic control truck body from a regular flatbed. If you’re interested in acquiring some Traffic Pro Bed components to build your own traffic control truck, please submit the requested information at the bottom of the page and we will be in touch.

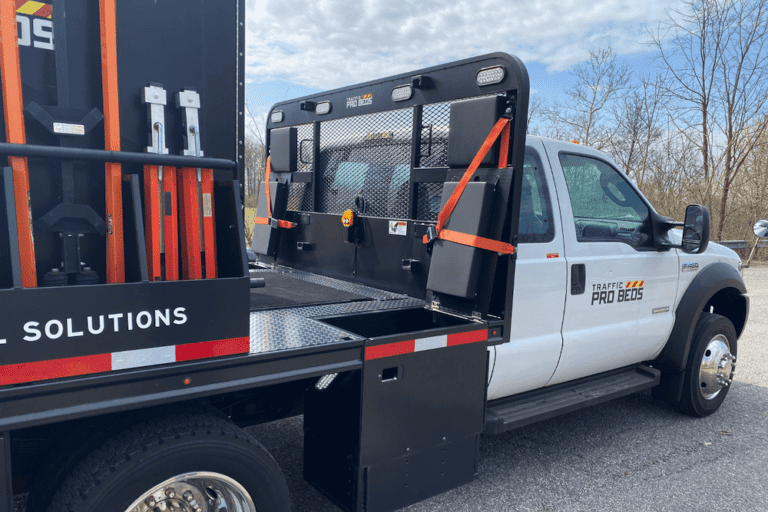

The Employee Safety Unit (ESU) with Safety Restraint System

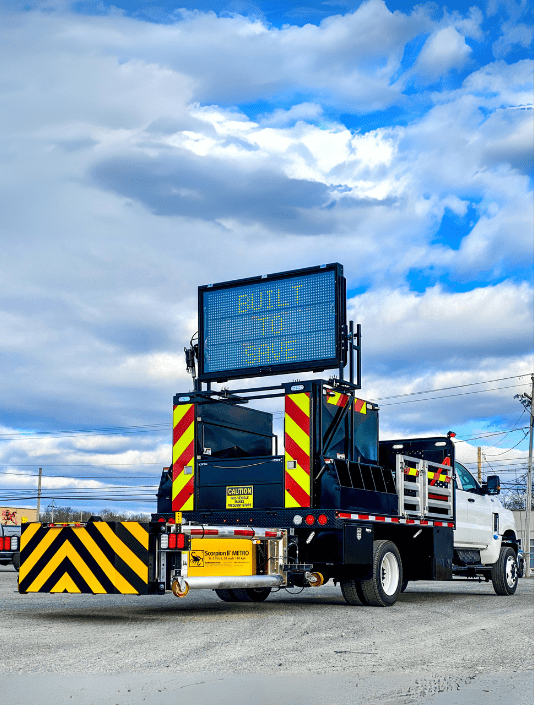

Located right behind the truck Chassis, on the outside of our Traffic Pro Bed, our personnel buckets are optimally positioned to maximize safety, communication, and visibility between workers during the job.

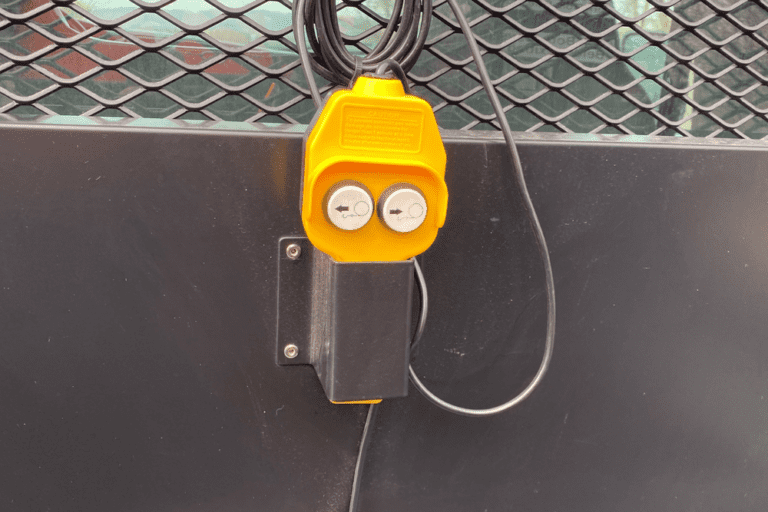

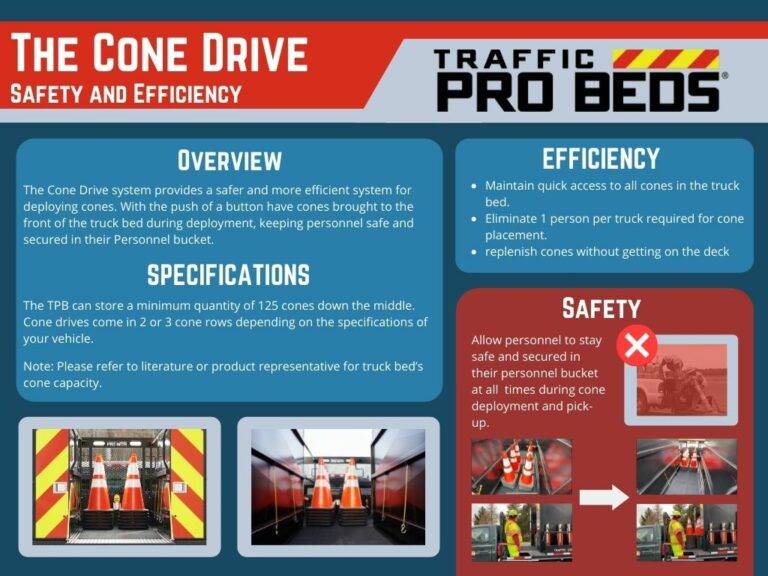

The Cone Drive System

Adding the cone drive to any truck bed is a simple and easy way to save both time and money, with no compromise to worker safety and efficiency. While secured inside a personnel bucket, workers can operate the belt drive and place cones simultaneously. This ensures a worker always has uncompromised access to all cones and space in the bed while deploying or picking up devices, without needing to coordinate with other workers or step out of the security provided by the Personnel Bucket.

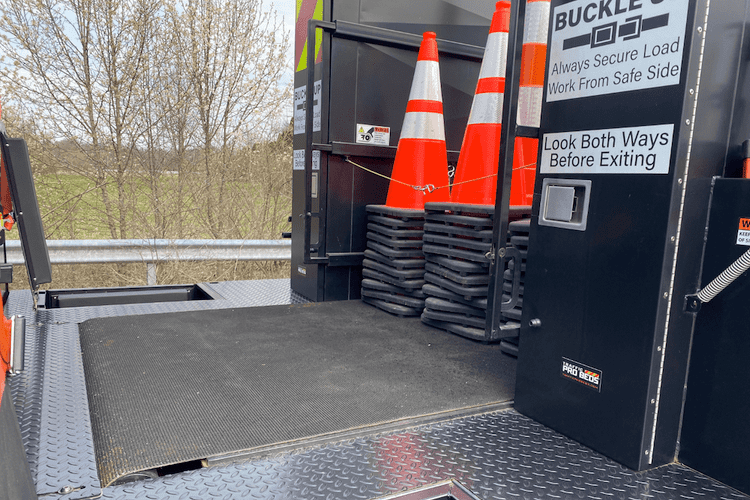

The Sign and Stand Box

More than anything, the sign, and stand boxes allow our customers to maintain organization in the back of their truck beds. Our patented design will enable workers to store each sign and stand safely and securely in its own designated spot on the bed while retaining equal accessibility among them. With this unique storing design, there’s no need to pile or dig through equipment, making the goal longevity of your equipment like never before.

The Employee Safety Unit (ESU) with Safety Restraint System

Located right behind the truck Chassis, on the outside of our Traffic Pro Bed, our personnel buckets are optimally positioned to maximize safety, communication, and visibility between workers during the job.

Did you know seatbelts are required for all passengers in moving vehicles in 31 State? Click to see if your state is one of them. Each Personnel Bucket is equipped with a seat belt based safety restraint system that allows workers extra security while retaining a high level of dexterity, maneuverability, and range of motion. The bucket can also be closed on the top to create more bed space or use as a secondary storage space.

The bucket itself is fully protected by the bed from three directions, and features a thick metal door on the exterior side to help shield against collisions. These personnel buckets are height adjustable and padded to help keep workers comfortable and free of fatigue. The fully enclosed box design allows workers to retain secure leg positioning in the bucket, minimizing fall risk.

– Safety Restraint System brings personnel into OSHA compliance. Click here for our OSHA Compliance video.

– Safety Restraint System secures personnel in Personnel Bucket to prevent workers from being launched from the truck during collision.

– Personnel Bucket is located where it is least likely to be the first point of impact and most shielded by the truck bed during collision.

– Access cones and other devices without climbing up into the bed.

– Easily step up into the truck bed using the Personnel Bucket’s corner steps.

– Leg and back padding prevents bruising resulting from rough roads or driving.

– Personnel Bucket is height adjustable to prevent curb strike and accommodate personnel height.

– Restraint system is height adjustable to accommodate personnel height.

– Store additional devices in Personnel Bucket.

– Personnel Bucket can be closed to create more deck space for devices.

200 Series

Truck Specifications: ¾ to 1 ton SRW truck with a 60” CA

Measurements: 27” L x 17” W x 29” H

Weight: 107 lbs.

300 Series

Truck Specifications: DRW truck with at least a 60” CA

Measurements: 27” L x 21” W x 33” H

Weight: 129 lbs.

To learn more about each series we offer and their specifications please refer to Specs & Series

The Cone Drive System

Adding the cone drive to any truck bed is a simple and easy way to save both time and money, with no compromise to worker safety and efficiency. While secured inside a personnel bucket, workers can operate the belt drive and place cones simultaneously. This ensures a worker always has uncompromised access to all cones and space in the bed while deploying or picking up devices, without needing to coordinate with other workers or step out of the security provided by the Personnel Bucket.

By adding the cone drive to a bed, a manager effectively decreases the number of personnel required on the back of the bed. Not only does this increase efficiency on the back of the bed, but it saves the company approximately 25 – 33% in wages per truck by cutting the required number of personnel. ROI analysis has revealed that the cone drive option essentially pays for the entire cost of the TPB in less than two years in reduced labor and related costs.

– Reduces the need to have personnel standing in the truck bed unsecured during deployment.

– Reduces the required number of personnel for an operation.

– Reduces the need to lift cones.

– Reduces required personnel for an operation.

– Provides personnel with more cones with the push of a button.

– Helps reduce time on the road by an estimated 15 minutes per work zone per day.

– Increases cone longevity.

– Reduces number of personnel required for an operation.

The Sign and Stand Box

More than anything, the sign, and stand boxes allow our customers to maintain organization in the back of their truck beds. Our patented design will enable workers to store each sign and stand safely and securely in its own designated spot on the bed while retaining equal accessibility among them. With this unique storing design, there’s no need to pile or dig through equipment, making the goal longevity of your equipment like never before.

Another optimal feature of the sign and stand box design is its access points to equipment. With the unit’s strategically positioned doors and stand boxes on both sides of the vehicle, workers have access to signs and stands while being shielded by the vehicle in all normal circumstances.

Additionally, this component comes with work lighting inside each sign box to make locating the right sign easy.

– Dual Sign and Stand Boxes always allow safe access to devices during set up.

– Devices are easily accessible without having to climb into the truck bed.

– Safety bar system prevents cones from falling onto personnel.

– Device storage prevents signs and stands from falling on to personnel.

– Holds 10 Small Stands or 5 Large Stands per unit.

– Holds 16 roll up signs or +16 Dibond signs per unit.

– Provides distinct spaces to store signs and stands.

– Naturally creates space for cones.

– Easily remove to create more room in the truck bed.

– Easily install to a flat bed.

Measurements: 71” L x 26” W x 56” H

Weight: 299 lbs.